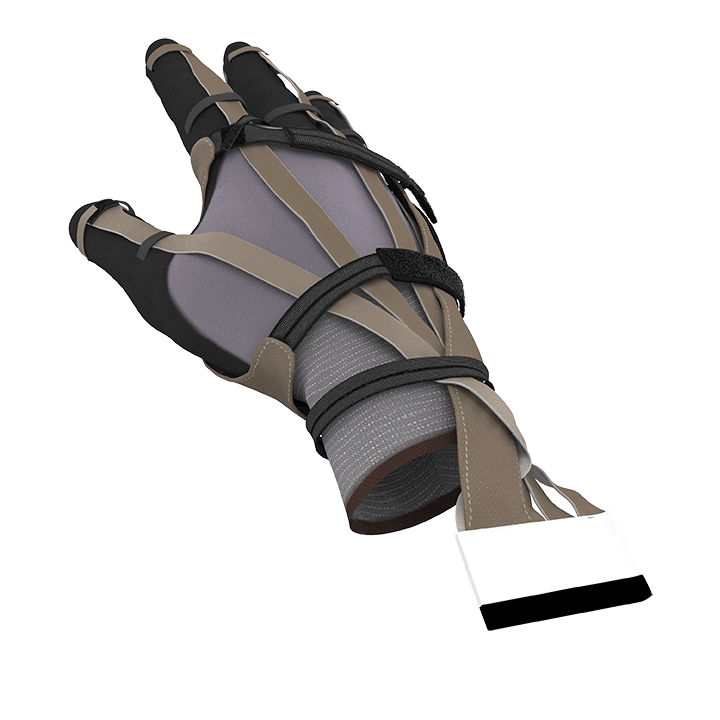

pliance® glove sensor

Despite the progression of technology, many tasks in the workplace and in daily living must be performed with the hands. Furthermore, it remains a challenge to quantify the manner in which hands are being used and with what level of intensity. These measurements are very important; especially if a task requires repetitive motion, is exhausting, or requires high precision.

The ability to measure force distribution across the hand provides a perfect basis for the monitoring of hand forces during routine tasks, for the improvement of working conditions, and for the development of optimized hand tools.

The pliance® glove system offers state-of-the-art technology for force distribution measurement of the hand. The system consists of flexible and elastic measuring sensors, a multi-channel analyser, a calibration device, and a software package for Windows PC.

The pliance® glove system is primarily designed for measuring force distribution across the hand while using manufacturing and production tools. These measurements may be used to reduce stress on the hand either by providing ergonomic assessment and feedback during the occupational activities or by providing critical data for modifying and improving the standard working process and redesigning the tools.

The system may also be used in physical therapy practice for assessing manipulations or for hand rehabilitation. Furthermore, it is useful for research in biomechanics, orthopaedics, and robotics.

As is the case for all physical measuring systems, the most important part is the sensor technology. Just like all novel systems, the pliance® glove system is based on calibrated, accurate, and reliable capacitive sensors. The individual sensor elements are elastic and arranged in a matrix which conforms well to three-dimensional shapes.

The pliance® glove sensors are a combination of five to twelve finger sensors and one palm sensor consisting of 64 sensors in a matrix arrangement. All critical hand surfaces are covered and the grip force of the hand can be measured. The unique design of the sensors conforms to the shape of the hand allowing various handgrips to be tested in different situations.

Worker’s health – Clapper loaders

Pliance glove can ensure that the worker’s health of clapper loaders is not risked while doing their job.

The pliance glove with it’s soft capacitive sensors can be used to monitor the hand movements and posture of clapper loaders to ensure that they are not putting themselves at risk of injury.

The sensor can be integrated into the handle of the clapper board, for example, and can detect when the worker is holding the board in an awkward or dangerous position. The sensor can then send a signal to the worker, either through an audio or visual cue, to adjust their posture or grip to a safer position. Additionally, the sensor data can also be analyzed to identify patterns of movement that may lead to injury over time and provide feedback to the worker and/or employer on how to reduce the risk of injury.

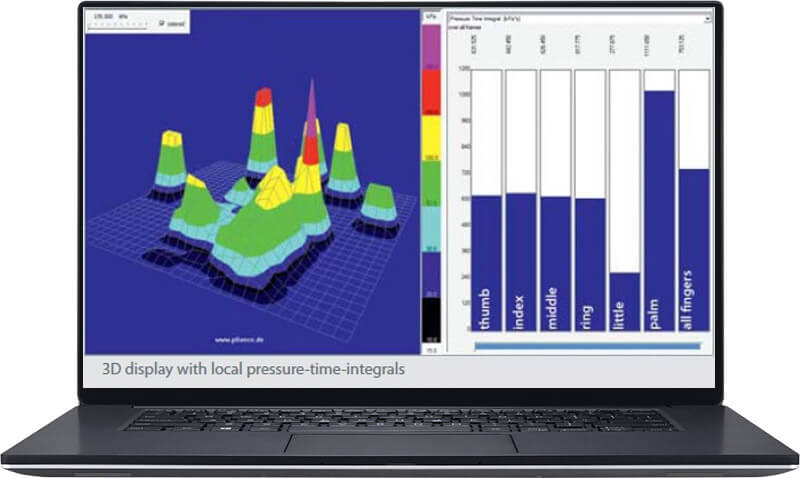

pliance® software

The pliance® software operates as a Windows application and allows easy data collection of load distribution. Data can continuously be stored in online mode and handled with a configurable SQL database. Different levels of pliance® measuring software are available. Using novel scientific software the expert is also able to design the parameter configuration to specific needs and exchange data with colleagues via HTML protocol. Individual reports can be created by the user to allow quick and easy data analysis.

trublu® calibration device

With the aid of the trublu® calibration device, all pliance® sensors are individually and simultaneously calibrated with homogeneous air pressure. Alternatively, special weights are available to calibrate individual sensors. Calibration guarantees accurate and reproducible data collection.

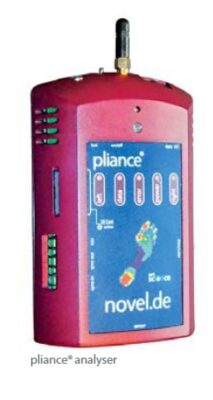

pliance® analyser

The pliance® analyser can collect up to 1,024 sensors and is specially developed for mobile measurements. It has a wide range of options, such as master-slave synchronisation of several systems, dynamic amplification control, biofeedback by sound or vibration, and synchronisation of video systems.

The pliance® analyser technology allows individual calibration curves for each sensor and also individual dynamic amplification control and crosstalk suppression, resulting in very accurate and reproducible pressure values. The pliance® analyser communicates with the PC via fibre optic/USB interface or via

Bluetooth®.

Features of the pliance® glove system

• Conforms perfectly to the hand grip

• Monitors simultaneously different anatomical areas of the hand

• Each sensor is individually calibrated

• Can be synchronised with video and other systems like EMG or 3D motion analysis systems

• 2D, 3D display, or isobar display

• Allows manifold analysis of measurement data

• Allows ASCII output

Possible applications

• Manipulation of tools

• Occupational medicine

• Ergonomics

• Physiotherapy

• Rehabilitation

• Sports

• Biomechanics

• Orthopaedics

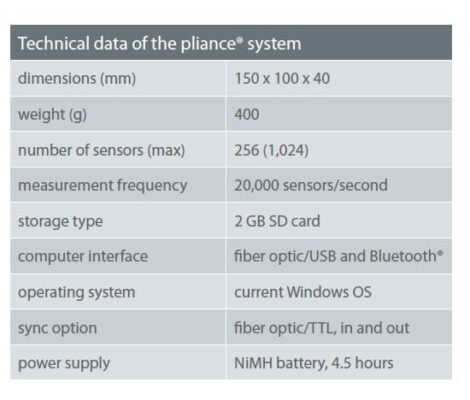

Technical data of the pliance® system