Body pressure mapping on bed and mattresses

How could novel sensors improve the construction, quality and comfort of bed mattresses?

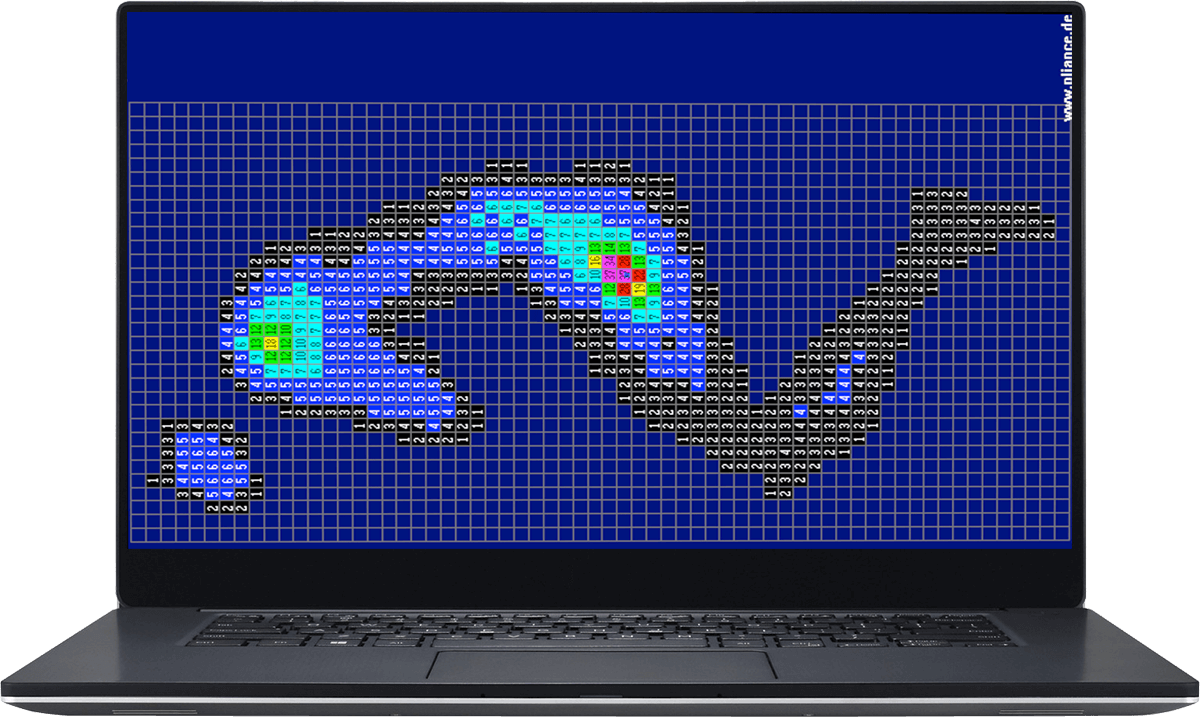

The pliance sensors can be used to measure pressures on soft, deformable surfaces by detecting changes in their capacitance caused by the weight and movement of a person on a bed mattress. These sensors can be arranged in a matrix configuration to provide a detailed map of pressure points and peaks. This information can be used to identify areas of the mattress that may be causing discomfort, or, even more important hinder the development of pressure sores (decupitus ulceration) and to design and manufacture mattresses that are more comfortable and supportive.

novel’s surface-compliant pliance sensors conform very well to the 3d shape of the mattress and provide accurate measurements of pressure distribution across the entire surface of the mattress. This ensures that all areas of the mattress are properly monitored and that any discomfort or pressure points of risk are identified.

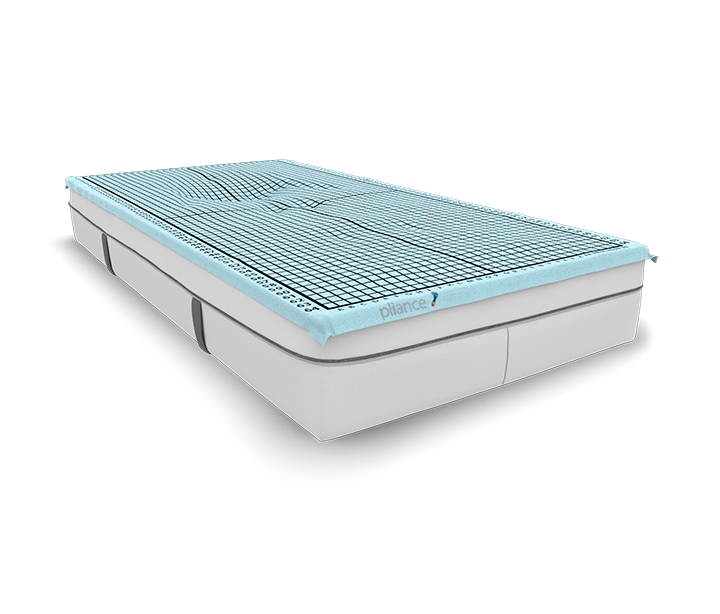

large size bed rest sensor mat

novel has developed a large size bed rest sensor mat that covers the full area of a mattress. The mat is highly elastic and conforms perfectly to the surface of a mattress under body load. As with all novel systems the sensors are calibrated accurately to the pressure range obtained during body contact.

Superficial pliance pressure distribution mats allow us to get measurements in soft and bended surfaces, adapting to the specific surface. The system consists of a flexible and elastic mat, an analyzer of multiple signals, a calibrator device and a measurement and analysis software of the pressure data.

pliance sensor mat

As in all physical measuring systems the most important part is the sensor technology. As all novel systems the pliance system is also based on calibrated, accurate, and reliable capacitive sensors. The individual sensor elements are elastic and arranged in a matrix which conforms well to three-dimensional shapes.

The pressure transducing elements contain high-tech elastomers manufactured by novel. Restoring force, range of force, threshold, hysteresis, temperature effect, frequency response, and other characteristics such as elasticity are determined during the manufacturing process. This makes it possible to adapt the sensor characteristic to different measuring needs.

Features of pliance sensor mat:

- elastic, fully stretchable

- highly compliant to 3D soft surfaces

- accurate, 5% ZAS

- low hysteresis 3% – 7%

- each sensor individually calibrated

- low temperature effect

Features of pliance software:

- easy to use

- Windows OS (Mac running Windows)

- multilingual

- integrated with novel database

- displays pressure time integrals, force time integrals and regional analysis of pressure and time variables

- allows multi-field analysis