Car Seat

Doors

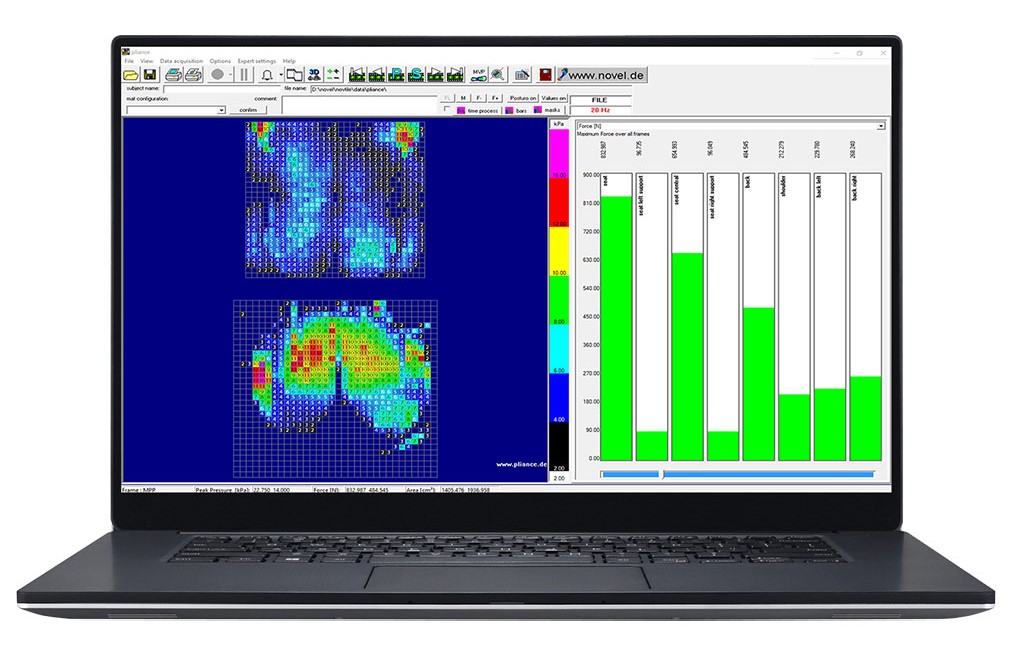

pliance for pressure measurement:

The pliance system’s high-resolution capacitive sensors are thin and flexible, allowing them to be placed in areas where traditional measurement tools might not fit or work effectively. This capability enables engineers to gather data from the actual points of interest, such as around the edges and corners of the door, without interfering with the door’s normal operation. The real-time data acquisition feature of the pliance system further allows for dynamic testing, such as measuring the impact of closing speed on pressure distribution and force impact, providing valuable data for optimizing car door design for performance, safety, and user satisfaction.

When applied to car doors, the pliance® system can precisely measure and analyze the force and pressure distribution exerted by or on the door seals, hinges, and latches. This is crucial for several reasons.

First, it helps in understanding how evenly pressure is distributed along the door seals, which is directly related to the effectiveness of the seal against water and air leakage, contributing to the vehicle’s overall acoustic insulation and weatherproofing. Second, assessing the force required to close or open a car door can provide insights into the ergonomic performance of the door design, ensuring that doors can be operated comfortably and safely by users of various strengths and abilities. Lastly, this system can evaluate the mechanical stress on different parts of the door under normal operating conditions, informing durability and maintenance considerations.

loadpad for force measurement

loadpad is another suitable option for measuring force, particularly in applications where you need to assess the load distribution characteristics under static or dynamic conditions. loadpad could be used to measure the force applied by or on a car door. loadpad could be utilized to evaluate the force required to close a car door, ensuring that it meets safety and usability standards without requiring excessive effort from users. This aspect of testing can contribute to the ergonomic design of car doors, making them more user-friendly, especially considering different user strengths and conditions (like wind resistance).

Seat Belt

loadpad can provide valuable insights into the force exerted by and on the seat belt system under various conditions. These data can be used for safety testing, ergonomic and comfort assessment.

As another choice, pliance system can be applied to measure and analyze the pressure and force distribution of seat belts on vehicle occupants. These measurements are critical for enhancing seat belt design, comfort, and, most importantly, safety.

pliance system known for its capability to measure pressure distribution between two surfaces, is particularly well-suited for evaluating how seat belts fit and distribute force across the body of occupants. This application is crucial for several reasons such as comfort and ergonomics, safety optimization, real-time dynamic testing.

Pedals

pedar system:

For measuring pressure on pedals in a car, such as the brake, accelerator, or clutch pedals, the novel pedar system is particularly well-suited. The pedar system is the gold standard tool for assessing the pressure distribution between the foot and the shoe or ground. The pedar system’s capability to provide real-time, dynamic pressure distribution data is crucial for understanding the ergonomic aspects of pedal design and operation. Engineers and designers can use this data to optimize the shape, size, and resistance of pedals to improve comfort and control for the driver, potentially enhancing the overall driving experience. Additionally, this data can inform safety studies by analyzing how quickly and effectively a driver can apply pressure to the brake pedal in various scenarios, or how pedal design influences driver fatigue over long periods.

pliance & loadpad

The choice between the pedar, pliance, and loadpad systems for measuring pressure and force on car pedals depends on the specific requirements of the study or test. The pliance system offers detailed pressure mapping capabilities, making it suitable for ergonomic and design optimization of pedals. The loadpad , focusing on total force distribution, can contribute to understanding the mechanical and durability aspects of pedal design. In practice, a combination of these systems might provide the most comprehensive insights into pedal design and functionality.

pedar pressure measurement insole

Steering Wheel

The pliance system is designed to assess pressure distribution between two surfaces, making it ideal for analyzing how drivers interact with a steering wheel. This interaction is critical for understanding and improving steering wheel design in Ergonomic Design, Material Testing & Safety Analysis. By mapping the pressure distribution across the steering wheel’s surface, designers can identify areas where drivers typically apply more pressure. This data is invaluable for optimizing the shape and material of the steering wheel to reduce fatigue and improve grip comfort during long drives.

loadpad system as another tool can offer valuable insights into the overall force exerted on the steering wheel, which is useful for several aspects of steering wheel design and safety tests.