Pliance-RLS prosthesis: Pressure between human and prosthesis.

The problem with the adaptation of prosthetic sockets is that they are not optimally adjusted; for example, in a thigh or leg prosthesis, it is important to have optimal force transfer between the prosthetic socket and the amputation stump (the residual limb) because the bony structure is no longer present after amputation, which means that forces must be transferred through soft tissues to the prosthetic socket. The problem with this is that the muscles change shape when contracting and the socket remains static. A compromise must be made between the fit of the static socket and the dynamic changes of the amputation stump due to muscle contraction. Sockets are usually held in place by suction on the amputation stump, which means that a certain minimal pressure between the amputation stump and socket surface is necessary, but at the same time the pressure must not be too high in order to maintain comfort and prevent injuries.

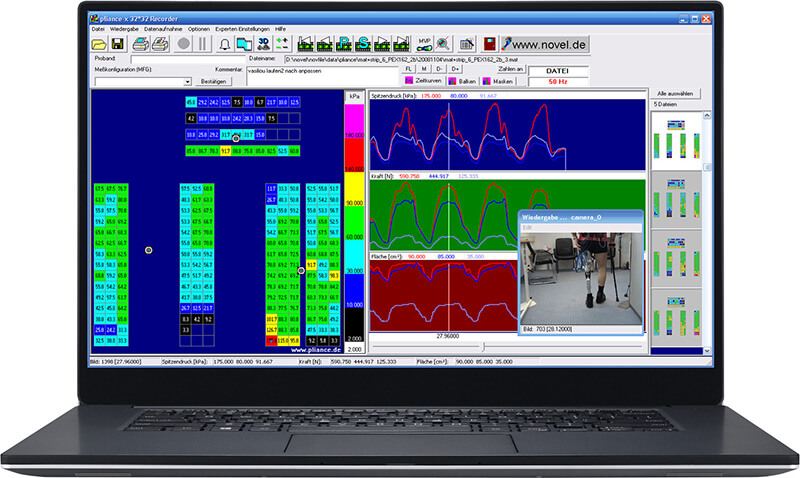

pliance sensors can help in the analysis of the optimal pressure between the socket and amputation stump through pressure distribution measurement to ensure appropiate pressure.

Pliance measurements can ensure to maintain comfort and prevent injuries while still ensuring proper fit and function of the prosthetic socket.

The pliance-RLS prosthesis system has been developed for socket evaluation and fit. It provides a quantification of the level of pressure at the residual limb/socket interface during static and dynamic movements.

As a result of their design and material selection, the pliance-RLS sensors are flexible and elastic and have the ability to conform very well around highly contoured sites. This is particularly advantageous in prosthetics because of the highly irregular surface and geometry of the residual limb and the shape of the socket.

The pliance-RLS sensors include a dense array of sensors, with a small individual sensor area. This allows recording of interface pressure at a discrete location of the socket. The length of the sensor pad is appropriate for use on a short or long transtibial socket.The different standard shapes allow testing of different

anatomical areas simultaneously. Custom made sensors are also available.