pliance support

Find answers to your questions on how to utilize pliance

Find answers to your questions on how to utilize pliance

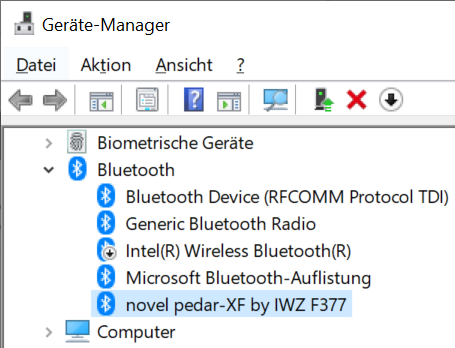

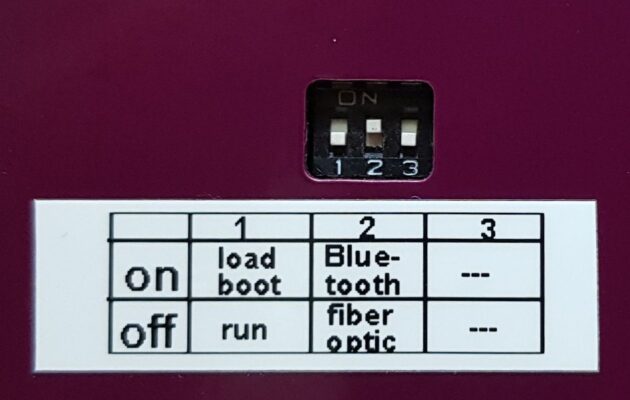

This is how to connect the pliance system to a Windows computer via BT:

Sena Dongle

A Bluetooth connection may fail for several purposes.

Ensure that there is a clear path (no visible obstructions between the Bluetooth dongle and the pliance analyzer antenna). A USB extension cable (up to 5 meters) can be used in conjunction with the Bluetooth dongle to allow the Bluetooth dongle to be placed on a tri-pod or other pole to position the Bluetooth dongle in an unobstructed view with the pliance analyzer.

Check if the pliance sensor plug is inserted into the cable connector completely and with the correct orientation.

The R on the sensor plug must line up on the same side as the R on the cable connector.

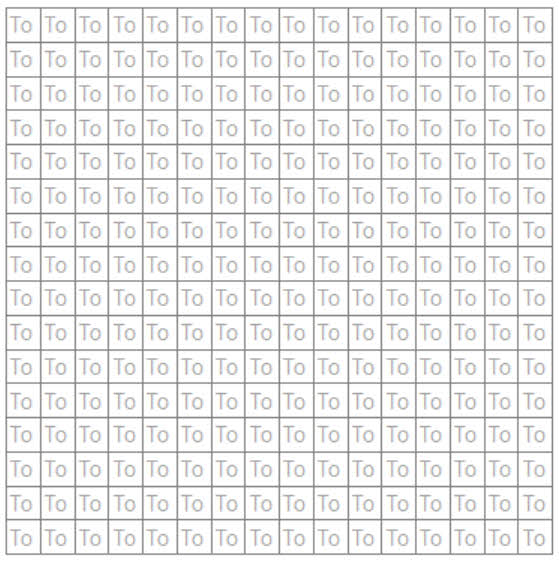

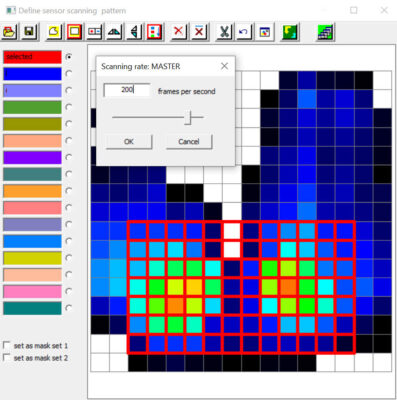

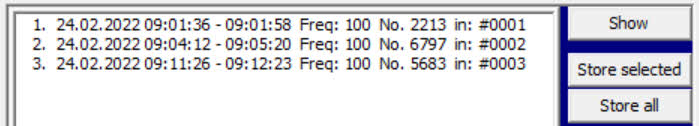

The maximum sampling rate for the pliance analyzer is 20,000 sensors per second. Usually a sensor is delivered with a configuration scanning all sensors of a mat with the highest possible scanning rate. If the number of sensors collected from is reduced, the sampling rate can be increased:

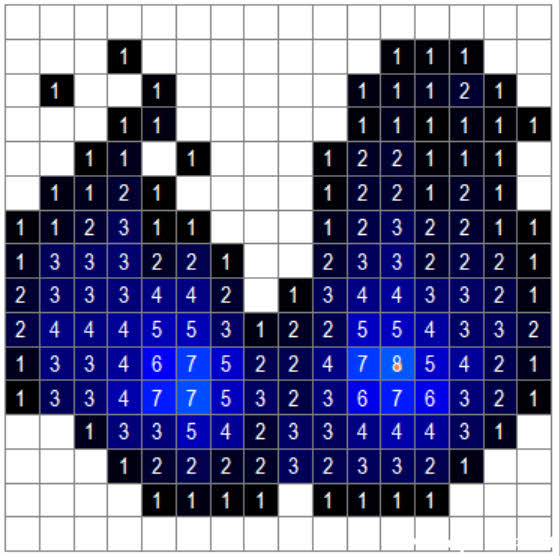

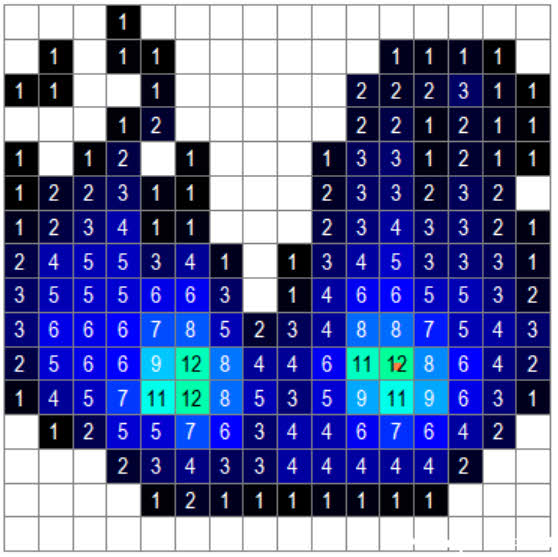

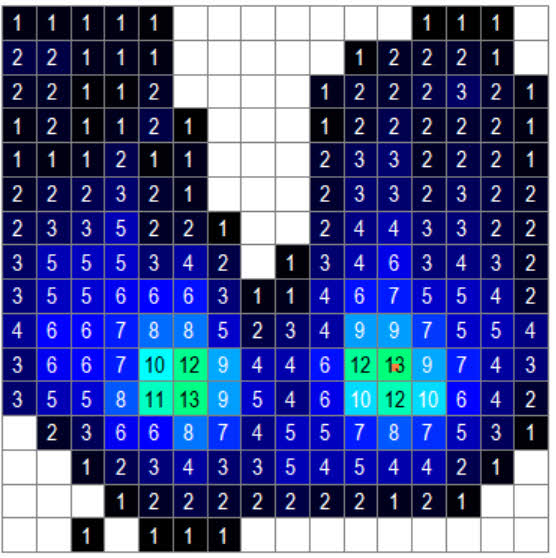

There are three options for the MVP calculation: over all frames, only over loaded frames, and only over loaded sensors:

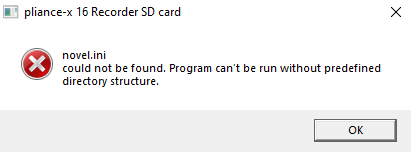

This error is caused by a corrupted cfg file of the pliance software. The cause may be a messy termination of this software, perhaps due to a crash or something similar.

To solve the problem,