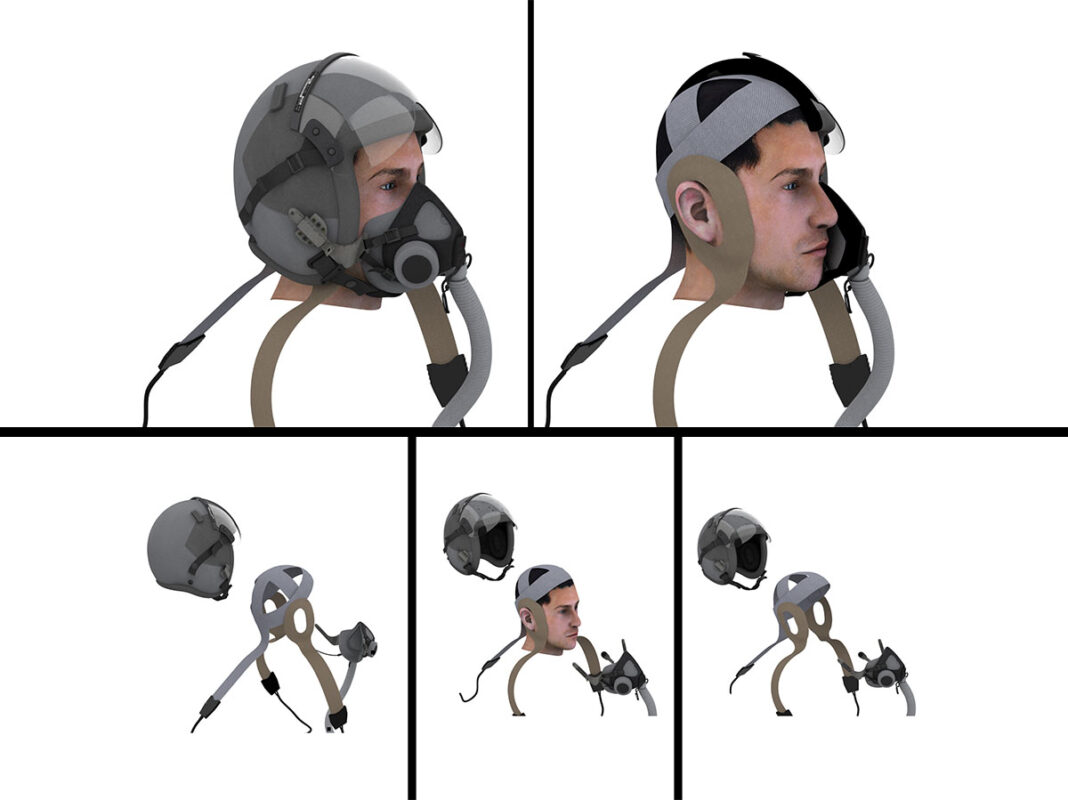

Pressure mapping inside helmet

Helmets are an essential piece of safety equipment used in a wide range of activities such as cycling, skiing, motocross, and construction work. A helmet that is both safe and comfortable is crucial for the wearer to be able to focus on their activity and perform at their best. A good fit of the helmet is also very relevant to safety: If the helmet slips before or during the first impact, the head is no longer optimally protected. Additionally, the pressure caused by a helmet can lead to discomfort, headaches and even pain. However, achieving the perfect fit can be challenging, as every person’s head shape and size is unique.

Optimizing comfort and safety of helmets

To improve the comfort and safety of helmets, soft surface pressure sensors can be placed between the helmet’s padding and the head. These sensors measure the pressure distribution across the head, allowing for the detection of areas of high pressure. This information can be used to adjust the fit of the helmet, or to design helmets with improved comfort and safety features. For example, the data from the sensors could be used to design helmets with adjusted padding in areas where pressure is high, or to create helmets with adjustable fit that can be tailored to the wearer’s head shape.

To be suitable for use in helmets, pressure sensors need to be thin, soft and conformable, as well as able to withstand the wear and tear of regular use. They should also be able to provide accurate and reliable data, even in extreme conditions such as high temperatures or humidity.

The pliance® sensor offers state-of-the-art technology for measuring the pressure distribution between soft and hard as well as curved surfaces. Each sensor element of the pliance helmet sensor comes with an individual adjustment. This ensures that both static pressure loads and dynamic pressure changes are measured accurately and reliably over the whole area of the helmet sensor. Its form allows it to be used for testing a wide variety of helmet designs.